Energy saving

Model and Full Scale Evaluation of PBCF Fitted to an Aframax Tanker

"Model and Full Scale Evaluation of a 'Propeller Boss Cap Fins' Device Fitted to an Aframax Tanker"

SMP'11, Hamburg Germany, June 2011

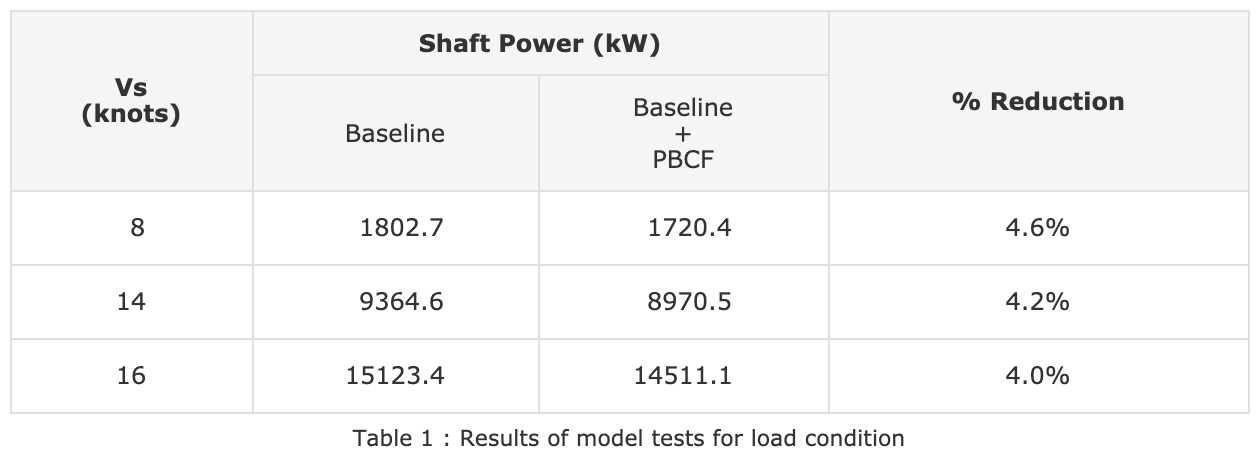

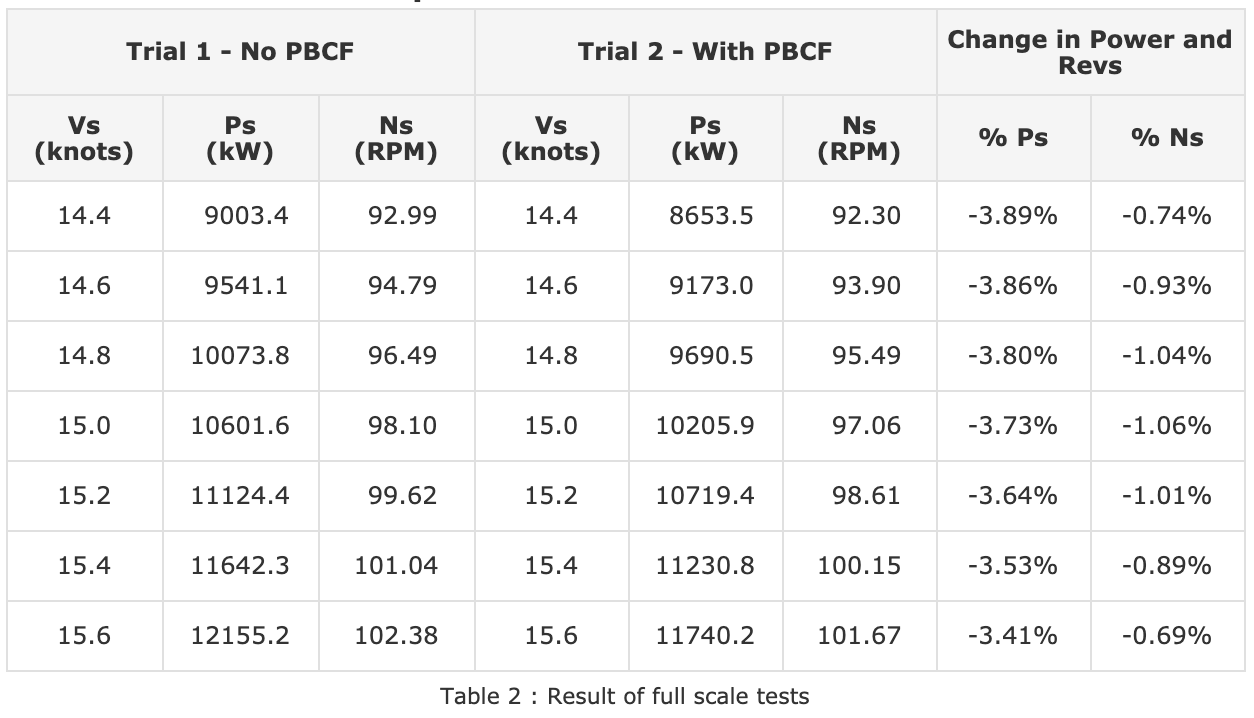

Teekay Corporation started a technology development programme in 2006. The programme consisted of a number of projects aimed at improving the efficiency of both existing and new build vessels. The PBCF device was one of the devices tested at model scale. In view of the positive results of the PBCF model tests, Teekay decided to conduct a full scale ship trial on the Aframax tanker Kilimanjaro Spirit. The Vessel underwent a carefully controlled sea trial right before the PBCF was fitted afloat. The sea trials were then repeated right after fitting.

The trial results conformed very well to the predictions from the model tests and showed that the PBCF device offers a useful reduction in shaft power and hence fuel efficiency.

Faired Results at Even Speeds

After the tests were completed, the effectiveness of the PBCF was considered to be sufficiently verified to make it possible to make a decision on the implementation of the PBCF in the Teekay oil tanker fleet. With the approximate 3.5% savings predicted, the pay-back time for the Aframax and Suezmax tankers were predicted to be about 6 months. This was well above the cost effectiveness required.